Lothian Renewables Ltd

07970 675 692

We are a locally based design and installation company specialising in Solar PV and Thermal systems and can also provide ongoing service and maintenance of both technologies.

Solar PV

We are specialists in solar PV covering all of Scotland, click to find out more.

Solar Thermal

We are specialists in solar thermal, click to find out more.

Loft Insulation

We are Logic Certified for loft insulation installation to CWL2, CWLIECI. Insulating your loft can be the single-most important energy saving choice you make. Grants are sometimes available to cover all or most of the cost, please contact us for details.

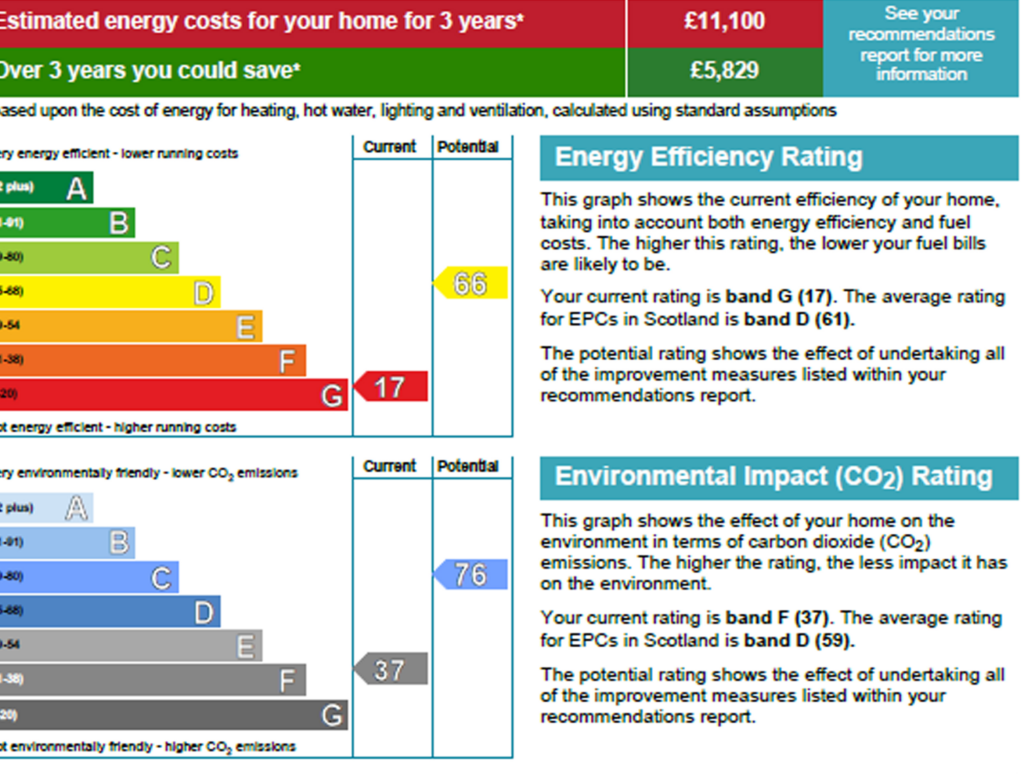

Energy Performance Certificates

We can provide cost effective Domestic Energy Performance Certificates required for grant applications

To find out more about home energy advice, support and grants for householders, click the button below to connect to up to date information from the Energy Savings Trust.